views

In CNC machining, precision, stability, and performance often come down to the quality of your tool holding system. One of the most commonly used standards in milling operations is the CAT 40 tool holder. But with a wide range of styles, specifications, and applications available, choosing the best CAT 40 tool holder can be overwhelming.

This guide breaks down the essential factors to consider so you can make an informed decision based on your machining needs, tooling setup, and performance goals.

What Is a CAT 40 Tool Holder?

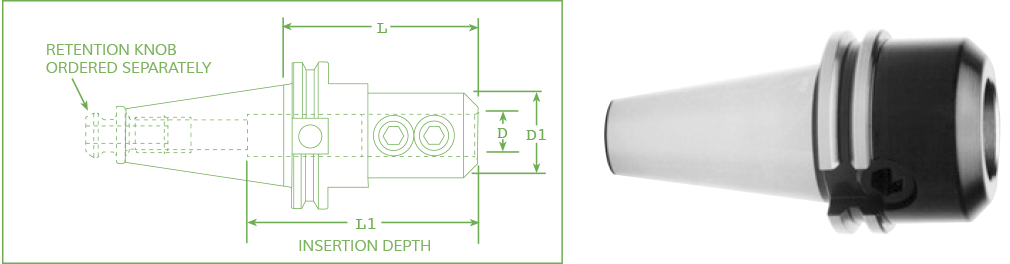

A CAT 40 tool holder is a type of V-flange tool holder standardized by the Caterpillar (CAT) system. The “40” refers to the taper size, which is smaller and lighter than the CAT 50 variant, making it suitable for medium-duty CNC milling machines.

CAT 40 tool holders are designed to fit into spindle tapers and are secured via pull studs. They provide a rigid and repeatable interface between the machine and the cutting tool, which is essential for achieving consistent, high-precision results.

1. Determine Your Application Requirements

Before selecting a tool holder, consider the types of operations you’ll be performing. Different applications require different levels of rigidity, tool length, and coolant capabilities.

- Milling: For general milling tasks, standard end mill holders work well.

- Drilling or deep cutting: You might benefit from a coolant-through CAT 40 holder that delivers coolant directly through the tool.

- Heavy-duty cutting: Shell mill holders offer greater support for larger cutters and roughing operations.

Understanding the scope of your work will help you choose a holder that balances performance and cost.

2. Check Machine Compatibility

While CAT 40 holders are standardized, it’s important to verify compatibility with your CNC machine’s spindle and drawbar system. Confirm:

- Taper size: Ensure your machine is designed for CAT 40 taper holders.

- Pull stud specification: Different machines may require different thread sizes or stud lengths. The pull stud must be correctly sized to ensure safe and reliable tool retention.

- Spindle speed: Some CAT 40 tool holders are rated for high-speed applications. If your machine operates at over 10,000 RPM, look for balanced holders to reduce vibration and wear.

3. Choose the Right Holder Type

CAT 40 tool holders come in various styles. Each has specific benefits depending on your tooling and operations.

- End Mill Holders: Rigid clamping for solid end mills

- Collet Chucks (e.g., ER): Versatility in tool diameter and high concentricity

- Shell Mill Holders: Suitable for face milling and large-diameter cutters

- Coolant-Through Holders: Ideal for deep hole drilling or heat-sensitive operations

- Taper Adapters: Allow compatibility with Morse or Jacobs taper tools

Selecting the appropriate style ensures optimal performance and prolongs both tool and spindle life.

4. Pay Attention to Tolerances and Balance

In high-speed or precision machining, tool holder quality becomes critical. Look for the following:

- Concentricity: Low runout (ideally ≤ 0.0002″) ensures better surface finishes and reduced tool wear.

- Balance: Tool holders used at high speeds (e.g., >10,000 RPM) should be dynamically balanced to ISO or G2.5 standards. This minimizes vibration and extends the life of both your machine spindle and tooling.

Higher precision holders may come at a premium, but they can reduce long-term tooling costs and improve part quality.

5. Consider Tool Length and Reach

Tool holders are available in various projection lengths—stub, standard, and extended.

- Stub length offers maximum rigidity for short-reach applications.

- Extended length provides necessary reach for deep cavities or complex geometries but can introduce deflection and vibration.

Always select the shortest length that meets your clearance requirements to maintain machining stability.

6. Don’t Overlook Material and Coating

The construction material of the tool holder affects durability and thermal stability.

- Alloy steel is commonly used for its strength and fatigue resistance.

- Surface treatments such as black oxide or nickel plating can help prevent corrosion and enhance wear resistance.

Choose tool holders from reputable manufacturers that meet industry standards for heat treatment and material consistency.

7. Maintenance and Safety Tips

Even the best tool holder can fail if not properly maintained.

- Clean regularly: Chips, oil, or debris on mating surfaces can affect runout and lead to tool slippage.

- Inspect pull studs: Worn or damaged studs can lead to tool drop or spindle damage.

- Store properly: Keep holders in racks or drawers that prevent nicks or corrosion.

Routine inspection ensures consistent performance and machine safety.

Final Thoughts

Choosing the best CAT 40 tool holder requires more than just picking the right size. By considering your machine compatibility, operation type, speed requirements, and tolerance needs, you can make a selection that boosts productivity and part quality.

Comments

0 comment