views

What Are Stainless Steel 304 Instrumentation Fittings?

What Are Stainless Steel 304 Instrumentation Fittings?

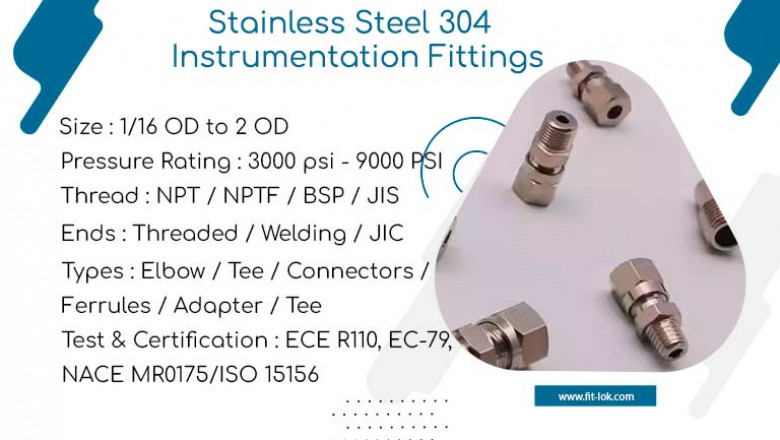

Precision-engineered parts called stainless steel 304 instrumentation fittings are used in piping systems to connect, regulate, and measure the flow of gases and liquids. High performance, corrosion resistance, and dependability are crucial in a variety of industries, including oil and gas, petrochemical, power generation, pharmaceuticals, food processing, and many more.

Material Overview – Stainless Steel 304

One of the stainless steel grades that is most frequently used is 304. It is mostly made of iron, with around 18% chromium and 8% nickel, and it is a member of the austenitic family of stainless steels. This composition is appropriate for a variety of industrial applications due to its superior strength, high-temperature resistance, and exceptional corrosion resistance. Furthermore, SS 304 has outstanding formability and weldability and is non-magnetic.

What Are Instrumentation Fittings?

In instrumentation systems that monitor and regulate process variables like pressure, temperature, and flow, instrumentation fittings are used to provide safe and leak-proof connections. These fittings are made to withstand high temperatures, high pressures, and corrosive conditions.

There are various types of instrumentation fittings, including:

-

Compression fittings: Used for leak-tight tube connections.

-

Tube fittings: Designed for reliable, easy installation and removal.

-

Pipe fittings: Threaded or welded, used in more permanent piping systems.

-

Adapters, unions, elbows, tees, and crosses: Allow for flexible configurations in complex piping layouts.

Why Choose Stainless Steel 304 for Instrumentation Fittings?

-

Corrosion Resistance: SS 304 resists corrosion from many chemicals, atmospheric conditions, and various media, making it ideal for use in harsh environments.

-

Durability: These fittings have excellent strength and toughness, even at cryogenic temperatures.

-

Cost-Effective: Compared to other stainless steel grades like 316, SS 304 offers a good balance of performance and affordability.

-

Versatility: Stainless Steel 304 fittings are suitable for a wide range of applications, from clean environments like food processing to more demanding conditions in refineries and chemical plants.

-

Cleanability: SS 304’s smooth surface is easy to clean, making it a hygienic choice in industries like pharmaceuticals and dairy.

Applications of SS 304 Instrumentation Fittings

-

Oil and Gas Industry: For controlling pressure and flow in pipelines.

-

Chemical Processing: To ensure safe handling of corrosive fluids.

-

Pharmaceuticals: In sterile environments where cleanliness is critical.

-

Food & Beverage Industry: For hygienic and corrosion-resistant piping.

-

Power Plants: In high-temperature and high-pressure environments.

Conclusion

Instrumentation fittings made of stainless steel 304 are an essential component of contemporary industrial pipe systems. They are widely utilized in many different industries to ensure safe and effective operations because of their exceptional strength, dependability, and resistance to corrosion. Selecting SS 304 instrumentation fittings is a wise, long-term investment in quality and performance, whether you're installing new equipment or servicing old systems.

Comments

0 comment