views

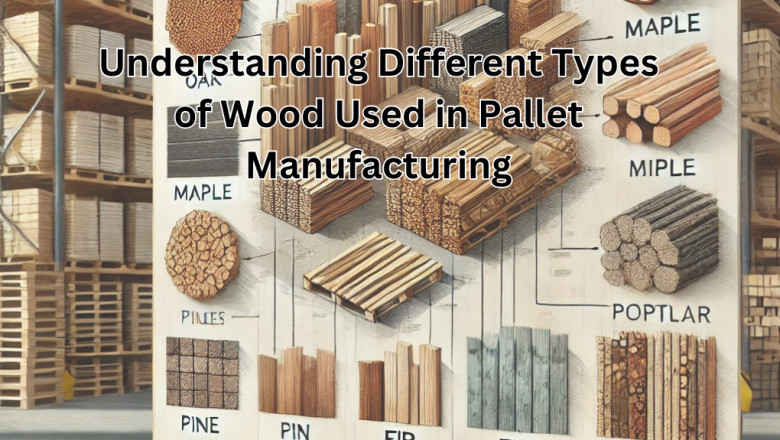

The type of wood used in pallet manufacturing significantly affects its durability, weight capacity, and cost. Understanding these differences helps businesses select the right pallets for their specific needs.

1. Hardwoods vs. Softwoods in Pallet Manufacturing

Wooden pallets are typically made from either hardwood or softwood, each with distinct characteristics:

-

Hardwood Pallets: Hardwoods come from deciduous trees such as oak, maple, and beech. These pallets are strong, durable, and capable of handling heavy loads. However, they are more expensive and heavier compared to softwood pallets.

-

Softwood Pallets: Softwoods, derived from coniferous trees like pine and fir, are lightweight and cost-effective. They are widely used in industries where disposable or single-use pallets are preferred.

Choosing between hardwood and softwood depends on the intended use and budget constraints.

2. Common Types of Wood Used in Pallet Manufacturing

A. Pine

Pine is one of the most commonly used woods in pallet production due to its availability, affordability, and lightweight properties. It is a softwood that provides good strength while remaining easy to process. Pine pallets are often heat-treated to meet export regulations and prevent pest infestations.

B. Oak

Oak is a hardwood known for its exceptional durability and strength. It is widely used in heavy-duty applications where pallets need to withstand substantial weight. However, oak pallets are relatively expensive and heavier, making them less suitable for one-time use.

C. Poplar

Poplar is a cost-effective alternative to oak and provides moderate strength. It is commonly used in manufacturing lightweight pallets for industries that require a balance between affordability and durability. Poplar is also resistant to splitting, making it a reliable choice for reusable pallets.

D. Maple

Maple is another hardwood frequently used in pallet production. It offers good shock resistance and durability, making it ideal for pallets used in harsh environments. However, its cost is higher compared to softwood alternatives.

E. Fir

Fir is a softwood that provides good load-bearing capacity while being lightweight. It is commonly used in export pallets due to its easy processing and availability. However, it is less durable than hardwood options.

F. Birch

Birch is known for its fine texture and high strength. It is commonly used in pallets that require high durability and resistance to wear. Birch pallets are suitable for industries where pallets undergo frequent handling and movement.

3. Factors Influencing Wood Selection for Pallets

A. Load Capacity

The strength of the wood determines how much weight a pallet can handle. Hardwood pallets are best for heavy loads, while softwood pallets work well for lighter goods.

B. Cost Considerations

Hardwoods are generally more expensive than softwoods due to their longer growth cycle and higher durability. Businesses often balance cost and performance when choosing pallet materials.

C. Moisture Content

The moisture level in wood affects its weight and susceptibility to mold. Kiln-dried wood is preferred as it reduces the risk of fungal growth and warping.

D. Environmental Impact

Sustainability is an important factor in pallet manufacturing. Many companies opt for recycled wood pallets or those sourced from sustainable forestry practices.

4. The Role of Wooden Pallet Manufacturers in Ensuring Quality

Pallet manufacturers play a crucial role in selecting the right type of wood to meet industry standards and client requirements. Wooden Pallet Manufacturers In Chennai and other major industrial hubs focus on providing high-quality, durable pallets tailored to different applications. They ensure compliance with international shipping regulations by using heat-treated or chemically treated wood to prevent pest infestations.

Conclusion

Choosing the right type of wood for pallet manufacturing is essential for ensuring durability, cost-effectiveness, and compliance with industry regulations. While hardwoods like oak and maple offer superior strength, softwoods like pine and fir provide affordability and ease of handling. By understanding the characteristics of different woods, businesses can make informed decisions when selecting pallets for their supply chain operations.

Comments

0 comment