views

Understanding Brushed Direct Current (DC) Motors: Design, Functionality, and Modern Applications

Introduction

In the vast realm of electric motors, brushed direct current (DC) motors hold a significant historical and practical value. These motors, characterized by their simplicity and effectiveness, have been widely used for more than a century. Despite newer, brushless variants becoming increasingly popular, brushed DC motors remain relevant in many industries due to their affordability, ease of control, and robust performance.

This guest post provides a comprehensive overview of brushed DC motors, detailing their working principles, components, benefits, limitations, and evolving applications. As electric mobility, robotics, and automation industries continue to grow, understanding the role and nuances of brushed DC motors is essential for engineers, hobbyists, and industry professionals alike.

1. Historical Background of Brushed DC Motors

Brushed DC motors trace their origin back to the early 19th century. The first practical DC motor was invented by Thomas Davenport in 1834. Later, the work of innovators like Frank Julian Sprague revolutionized motor control and efficiency, facilitating the spread of DC-powered systems in transportation and industrial settings.

Before the advent of alternating current (AC) systems, brushed DC motors were at the forefront of the electrical revolution. They powered early elevators, trolleys, and factory machinery. Despite the shift toward AC motors in many large-scale applications, DC motors persisted due to their controllability and ease of use in portable and battery-powered devices.

2. Basic Construction of a Brushed DC Motor

A brushed DC motor consists of the following key components:

-

Stator: The stationary part, typically comprising a permanent magnet or electromagnet, which creates a constant magnetic field.

-

Rotor (Armature): The rotating part that carries the current and interacts with the magnetic field to produce torque.

-

Commutator: A mechanical switch that reverses the direction of current through the rotor windings, ensuring continuous rotation.

-

Brushes: Conductive carbon or metal elements that maintain electrical contact with the rotating commutator.

-

Shaft: The central axis through which mechanical power is transmitted to the load.

This setup allows for a simple and reliable method of converting electrical energy into mechanical motion.

3. Working Principle of Brushed DC Motors

The operation of a brushed DC motor is based on Lorentz Force Law, which states that a current-carrying conductor in a magnetic field experiences a force. In a DC motor:

-

A DC voltage is applied to the armature.

-

The current flows through the brushes and commutator into the armature windings.

-

The magnetic field from the stator interacts with the current in the rotor.

-

This interaction creates a torque that causes the rotor to turn.

-

The commutator periodically reverses the current direction in the windings, maintaining unidirectional torque and continuous rotation.

The speed of the motor can be easily controlled by adjusting the supply voltage or by using pulse-width modulation (PWM) techniques.

4. Types of Brushed DC Motors

Brushed DC motors come in several configurations depending on how the field winding is connected to the armature:

-

Series DC Motor: Field winding is in series with the armature. Offers high starting torque but poor speed regulation.

-

Shunt DC Motor: Field winding is in parallel (shunt) with the armature. Provides good speed control and is used where constant speed is required.

-

Compound DC Motor: Combines series and shunt windings to balance torque and speed characteristics.

-

Permanent Magnet DC Motor (PMDC): Uses permanent magnets in the stator. Common in small appliances, automotive systems, and toys.

Each type has specific performance traits making them suitable for different applications.

5. Advantages of Brushed DC Motors

Despite being an older technology, brushed DC motors offer several advantages:

-

Simplicity: Straightforward construction and operation.

-

Cost-Effectiveness: Inexpensive to produce and maintain.

-

Ease of Speed Control: Speed is directly proportional to the applied voltage.

-

High Starting Torque: Especially in series-wound motors.

-

No Need for External Controllers: Unlike brushless motors which often require complex electronics.

These features make them attractive for cost-sensitive and portable applications.

6. Disadvantages and Limitations

Brushed DC motors are not without drawbacks:

-

Brush and Commutator Wear: Mechanical contact leads to friction, wear, and sparking.

-

Maintenance Requirements: Brushes require regular inspection and replacement.

-

Lower Efficiency: Energy losses occur due to brush friction and heat.

-

Noise and EMI: Brushes generate electrical noise, which can interfere with sensitive electronics.

-

Limited Lifespan: Particularly in continuous or high-load applications.

These limitations are especially critical in high-performance or long-duration operations.

7. Applications of Brushed DC Motors

Brushed DC motors are found in numerous domains due to their versatility:

-

Automotive Industry: Power windows, seat adjusters, windshield wipers, and starter motors.

-

Consumer Electronics: Toys, hairdryers, and small kitchen appliances.

-

Industrial Equipment: Conveyor belts, actuators, and hand tools.

-

Healthcare: Mobility scooters, hospital beds, and infusion pumps.

-

Aerospace and Defense: Precision instruments and small drones.

Their ability to operate on battery power and deliver immediate torque makes them ideal for mobile and compact devices.

8. Comparison with Brushless DC (BLDC) Motors

Brushless DC motors are increasingly favored due to improved efficiency and reduced maintenance, but brushed motors still hold their own in certain contexts:

| Feature | Brushed DC Motor | Brushless DC Motor |

|---|---|---|

| Maintenance | Regular | Minimal |

| Cost | Lower | Higher |

| Control Complexity | Simple | Requires controller |

| Efficiency | Moderate | High |

| Lifespan | Shorter | Longer |

| Noise | Noisy (brushes) | Quiet |

| Applications | Entry-level, simple | High-performance |

In low-cost or DIY projects, brushed DC motors are often the better choice.

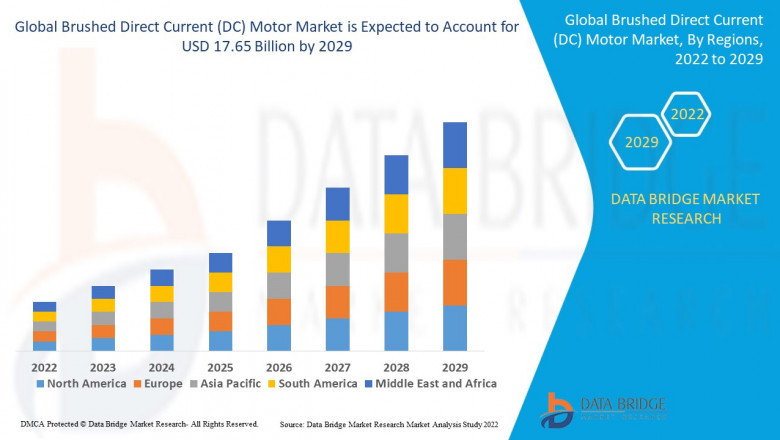

Source:- https://www.databridgemarketresearch.com/reports/global-brushed-dc-motor-market

9. Maintenance and Troubleshooting

To extend the life of brushed DC motors, regular maintenance is necessary:

-

Brush Inspection: Worn-out brushes should be replaced periodically.

-

Commutator Cleaning: Carbon buildup can be removed with a fine abrasive or specialized cleaner.

-

Lubrication: Bearings and shafts should be kept lubricated to prevent overheating.

-

Ventilation: Adequate cooling should be ensured to avoid motor burnout.

Common issues like reduced torque, noise, or erratic speed often stem from brush or commutator problems.

10. Innovations and Future Trends

Although overshadowed by brushless motors in many sectors, brushed DC motors are not obsolete. Innovations in materials and design are enhancing their capabilities:

-

Graphite and Alloy Brushes: Increase efficiency and reduce wear.

-

Hybrid Motors: Combine features of brushed and brushless designs.

-

Smart Motor Controllers: Enable IoT connectivity and real-time diagnostics.

-

Miniaturization: Emerging in micro-robots and wearables.

As long as cost, simplicity, and direct control remain priorities, brushed DC motors will continue to evolve and serve.

Source:-https://www.databridgemarketresearch.com/reports/global-brushed-dc-motor-market

Conclusion

Brushed DC motors remain a foundational element in the field of electromechanical systems. Their combination of simplicity, affordability, and functionality ensures their continued relevance in a world of increasingly complex technologies. Whether in small gadgets or industrial machines, their role in powering movement is indispensable.

Other trending reaports:-

Global Baby Monitors Market – Industry Trends and Forecast to 2029 https://www.databridgemarketresearch.com/reports/global-baby-monitors-market

Global Gallbladder Cancer Treatment Market – Industry Trends and Forecast to 2030 https://www.databridgemarketresearch.com/reports/global-gallbladder-cancer-treatment-market

Global Arterial Blood Collection Market – Industry Trends and Forecast to 2028 https://www.databridgemarketresearch.com/reports/global-arterial-blood-collection-market

Global Injectable Nanomedicine Market – Industry Trends and Forecast to 2028 https://www.databridgemarketresearch.com/reports/global-injectable-nanomedicine-market

Global I-Joist Market – Industry Trends and Forecast to 2028 https://www.databridgemarketresearch.com/reports/global-i-joist-market

Global Medical Sterile Gloves Market – Industry Trends and Forecast to 2028 https://www.databridgemarketresearch.com/reports/global-medical-sterile-gloves-market

Global Hematocrit Test Devices Market – Industry Trends and Forecast to 2028 https://www.databridgemarketresearch.com/reports/global-hematocrit-test-devices-market

Global Latex Gloves Market – Industry Trends and Forecast to 2028 https://www.databridgemarketresearch.com/reports/global-latex-gloves-market

Global Bio-based Agricultural Surfactants Market – Industry Trends and Forecast to 2029

https://www.databridgemarketresearch.com/reports/global-bio-based-agricultural-surfactants-market

Global Barley Flakes Market - Industry Trends and Forecast to 2029

https://www.databridgemarketresearch.com/reports/global-barley-flakes-market

Comments

0 comment